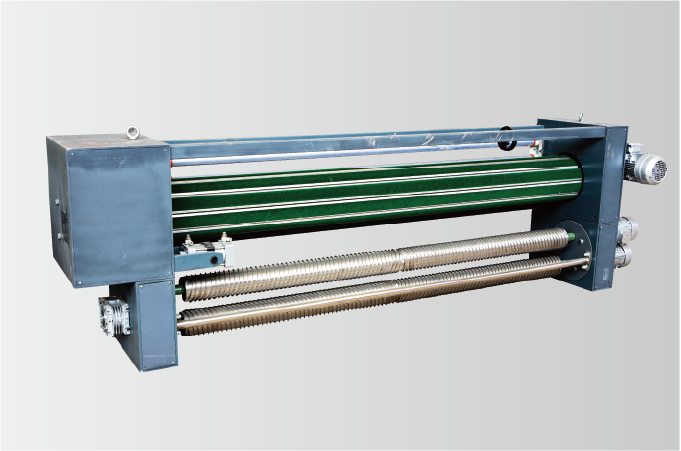

AIR SOFTENING MACHINE

Main technical specification

- Internal fabric accumulation: 30-80m

- Production speed: 3-70m/min

- Maximum treatment air temperature: 170°C(gas/diathermic oil) 150°C(steam)

- Installed electrical power: 90kw(200cm) 107kw(280cm) 119kw(320cm)

- Consumption on air heating: 63m³/h(gas) 39m³/h(diathermic oil) 780kg/h

GRID

DUST COLLECTING SYSTEM

ELECTRIC CONTROL SYSTEM

MULTI-POSITION AIR PISTON

EXPANDING &CENTERING DEVICE

FANS

MACHINE USAGE

Air softening machine is mainly used for all kinds of woven fabric, especially for 100% cotton, line, ramie, jute, wool and synthetic fibre fabric.It is also suitable for velvet, suede fabric, raising fabric, sueding fabric with soft and plump.The spandex fabric with slack and soft, the knitted fabric with preshrinking, slack and soft, the coating lining machinery softening finish, and the superfine fiber fabric with peculiar smell removal.And this machine can be used for leather instead of boarding machine.

WORKING PRINCIPLE

Air softening machine adopts the physical ways that it send the heated or normal airflow to the blowing box with 2500m/min.The wind power suck the fabric, and knead the fabric during the accelerated speed, when the fabric is blew out from the air pipe, the fabric will be bulking.When the fabric is hit onto the grid moderately, again and again.The airflow in the air pipe will protect the fabric as the air cushion, which ensure the fabric get strong but soft treatment.During the treatment, fabric and airflow, fabric and airflow, fabric and pipe inner, fabric and fabric, fabric and grid will be rubbed, kneaded, flapping again and again.And under the chemicals, the fabric fibre inner tension is deleted to make move, fluffy and micro-fibre, the fabric will be get smooth, soft and fluffy.